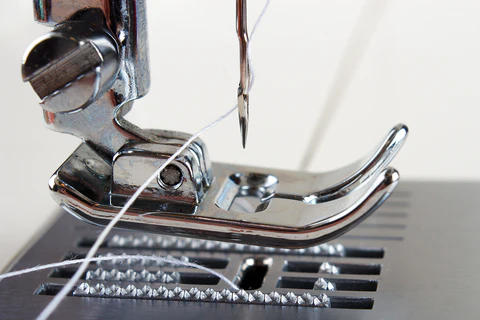

A feed dog is a set of metal ridges (or teeth) located on the inside of a needle plate that helps in moving fabric when you’re sewing. The feed dog mechanism is controlled by the foot pedal (just like the needle) and so the harder you press your foot against the pedal, the faster the feed dog will move your fabric. The teeth on the feed dog help grab the fabric, also accompanied by the pressure that the presser foot exerts on the fabric. The height of the feed dog can be adjusted according to the user’s preferences, when lowered the user has more control over the linearity of stitching since the feed dog also helps to sew in straight uniform lines.

Table of Contents

Needle Plates

The needle plate is commonly known as the throat plate. It is a removable metal case or shield found on all sewing machines, it is for the effective coverage of the bobbin area which the feed dog can also be found under. Some special needle plates have markings on them that guide your measurements of sewing, so as to effectively sew in straight lines in the case that the feed dog is lowered to a position that needs your complete input when passing the fabric through the presser foot. A good quality needle plate will help you sew perfectly with a slick metal surface that allows for the gentle push of fabric.

1. Feed Dog Is Not Raising

This feed dog problem can be caused by numerous factors, one being shifted or moved out of place by something, and in most cases can only be solved by manual tinkery.

To Do

It’s important to make sure that the presser foot is raised up when the feed dog is not raising. The feed dog lever should be in the up position. Then you should manually turn the handwheel towards you (or anticlockwise) until you hear a clicking sound. This clicking sound signifies that the feed dog is falling back into place.

2. Feed Dog Timing Is Off

This problem is usually caused by issues from the needle or bobbin area, whereby if the bobbin driver is moving at a slow or faster pace than you would normally appreciate, it affects the pace of the feed dog as well.

- The bobbin driver and feed dog are connected in such a way that if one of either were broken or damaged it would manifest (show up) in the other, creating a cause and effect dynamic.

To Do

Always analyze and observe your sewing machine, such that if any part is worn out or damaged, necessary action is taken. And when you start sewing make sure you set your stitch length to long and straight, this setting is essential for this type of problem.

- This problem will need you to take your sewing machine to a certified professional.

3. Feed Dog Breaking

This problem is not unique, a sewing machine’s feed dog is generally small and delicate (although it is made of metal.) When exposed to tough or rough fabrics frequently, the feed dog is prone to breaking, specifically where the ridge or teeth are located. Sometimes if the feed dog has loose screws, it become loose itself, which makes it wobbly and shaky where it will be constantly hitting and striking against the needle plate, causing it to break into two parts.

To Do

Fortunately when the feed dog breaks it is not the end of the sewing machine’s life. A feed dog can be replaced, but it is important that you know the specific size of your sewing machine’s feed dog, so you know which one to purchase. Always check the screws around your sewing machine and make sure they are as tight as they should be.

4. Feed Dog Dirt

This problem can actually hinder the movement of the feed dog and make it very difficult for you to move your clothing or fabric to the other side.

To Do

Luckily solving this problem is a no-brainer. Even when it is only a spec of dust, lint or debris the feed dog should always be cleaned every single day that you can. Especially after a sewing project, a gentle wipe on the needle plate (of which the feed dog is located under) would help immensely. A little dust can cause a lot of trouble if it accumulates, from jamming to complete stagnation of the feed dog.

- Always thoroughly wipe and then cover your sewing machine after using it.

5. Feed Dog Can’t Catch Fabric

Silky or fine fabrics cause this problem a lot for the feed dog. Due to the fabric’s silky or fine texture the teeth of the feed dog are unable to grip the fabric and so don’t work properly.

To Do

You can always adjust (by lowering) the pressure of the presser foot. The presser foot will push the fabric lower thus gripping the feed dog teeth and moving through accordingly.

6. Feed Dog Not Pulling Forward

This means that the teeth are not moving back and forth like they should be to pull the fabric forward. This problem is caused by the stitch length setting, which is essentially for adjusting how long or short the stitch length will be.

- This stitch length setting also affects the movement of the feed dog.

To Do

- When fine tuning your sewing machine before starting the sewing, it is important to set the stitch length in accordance with the type of fabric you will be using. Typical stitch length is zero and when changing a fabric you should adjust it to a higher number just the same. But stitch length should never be set to a very high number.

- The specifications can be found in your sewing machine’s user manual, meaning if the fabric is either polyester or nylon the user manual will have information on which stitch length setting you should pick and why.

- It is also critical to check that the bobbin is installed correctly in the bobbin case. A loose or out of place bobbin will cause the feed dog to hault in motion.