Clutches are very important systems in many vehicles including golf carts. The purpose of the clutch is to allow connection of engine power to the axle. EZGO golf cart makes use of clutches also known as continuously variable transmission (CVT). The transmission consists of two separate clutches, the drive or primary clutch and driven or secondary clutch which are linked together by thick drive belt. The clutch system or CVT experiences failure through wear and tear. In some cases the transmission may end up having problems requiring it to be adjusted as opposed to replacement. It is important to understand the nature of the problems common to the clutches in order to comprehend the clutch adjustment procedure.

Table of Contents

Why EZGO Golf Cart Clutch Needs Adjustment

The clutch may need adjustment mainly due to problems encountered with the clutch. Some of the problems that develop with clutch include clutch slipping. This problem of slipping causes the gears not to engage from neutral position. In some instances, noisy sound is produced when trying to change the gears. The clutch may also get stuck due to wear of primary and secondary clutch components. All these faults require clutch adjustments as discussed in this article.

Tooling Required

The process of adjusting EZGO golf cart clutch may be an easy process provided adequate tooling is provided. It is important to determine the tools required by visually inspecting the clutch assembly. All bolts requires proper size spanners or shifting spanner that is capable of loosening range of nut sizes. An impact gun may also be used for loosening nuts if available to save time. Where screws are available, there is need to have flat and star screw drivers depending on the screw type used. The dismantling of the clutch system may sometimes require rubber hammer for knocking some of stuck components without damaging them. The clearance of EZGO golf cart may require use of a jack to lift the cart so that clutch is easily accessible from underneath.

Dismantling the EZGO Golf Cart Clutch System

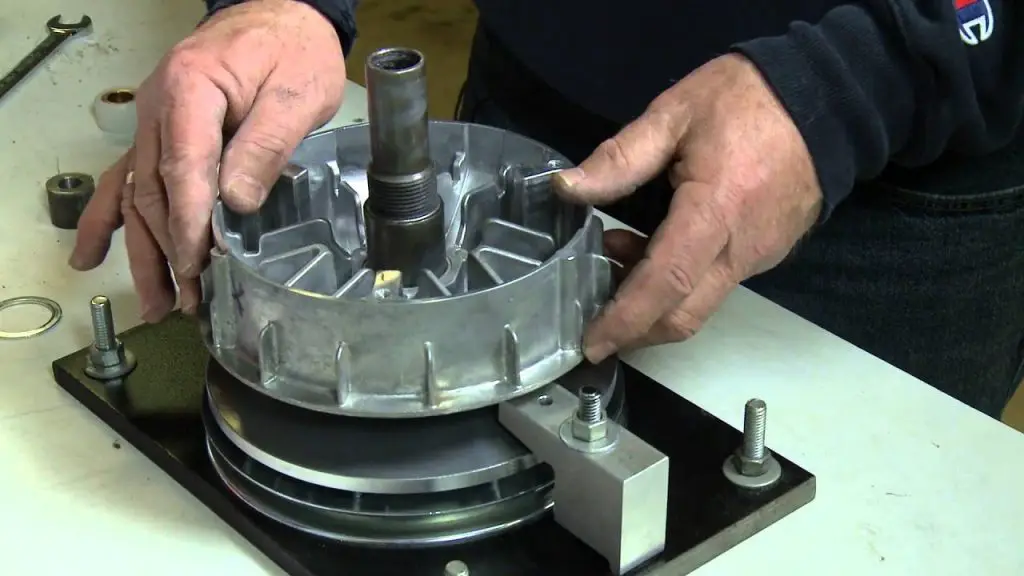

The dismantling of EZGO golf cart is the most tedious part of the clutch adjustment process. This is due to the tasks required to be done and awkward postures that are required sometimes to carry out a task. The first step in the dismantling process is to jack up your golf cart at the differential so that the clutch is easily accessible. Some EZGO golf carts may not need this step depending on the skill and tooling available for loosening the clutches. If using small size spanners it is possible to skip this step but awkward postures are required to access the clutches situated behind the wheel and cart frame components. After that the next step is to get an impact gun to loosen the primary and secondary clutch cap screws and take out the clutches. Always take note of the clutches so that they don’t get mixed up and used incorrectly or vice versa. Make sure that all bolts and nuts are stored where they can easily be retrieved. The screws maybe of different sizes and therefore make sure you identify which screw goes to which clutch. The clutch belt can now be removed from its position. This sums up the basic clutch disassembly process and the next step is to adjust the clutch.

Clutch Adjustment

After carefully disassembling the EZGO golf cart clutch, inspect the clutch for any sign of wear and tear. The splines should be well built otherwise if worn out they have to be replaced. The other obvious reason for clutch misbehavior is dirt and corrosion within the clutch interior. This corrosion or dirt has to be removed using wire brush. Also ensure that all buttons are in place for both primary and secondary clutches.

Having done these clutch adjustments, the clutches may be assembled and tightened waiting to be fixed back onto the golf cart. Like mentioned above always make sure not to interchange the clutches. Primary clutch and secondary clutch must both be fixed back to their positions respectively. With both clutches in position, check the clutch belt for tension and wear as this is known to be the common problem with clutches. The belt should be properly tensioned and in good condition. If the belt is not properly adjusted, adjust the belt properly otherwise if the belt has elongation it should be replaced with new belt and fixed back. Clutch belts can also be misaligned and hence they should be checked for misalignment and aligned where necessary. Clutch related problems should be solved by these adjustments. Some of the clutch internal parts should be cleaned and lubricated to make them more efficient. When all the steps are done the clutch adjustment on your EZGO golf cart is done and the next step is to assemble and test your clutch again.

Reassembly and Testing of The Clutch

Lastly the EZGO golf cart clutch and various components have to be assembled back and all bolts and screws secured back. Make sure all bolts are put back so that clutch elements are fixed to avoid wobbling and damage to the clutches and shafts. Replace the wheel in case it had been removed for clearance and easy access to the clutch. Remove the jack and clear all tools. Then test your EZGO golf cart clutch and see how it performs. Normally after these adjustments the clutch should perform well despite service life not being guaranteed due to nature of repair job. It is recommended to ask for assistance when performing clutch adjustment if not sure of how to carry out the process. Various golf cart suppliers provide manuals that cover these issues in greater detail. Use of the manuals as primary reference is highly recommended.

Above all, clutch failure may be as a result of poor operator skills and poor maintenance practices. Asset depreciation also plays a part in golf cart clutch misbehavior. These root causes can be eliminated with a proper maintenance planning and scheduling. All periodic inspections and service as scheduled by supplier should be religiously adhered to.